2025 Simmer Blacktip

£589.00 – £689.00

Simmer 2025 Blacktip Sails

Competition Wave Performance

The 2025 Blacktip sail has been meticulously engineered with a singular focus: equipping Marc Paré with the optimal tool to achieve his ambition of becoming the Wave World Champion. During the design collaboration between Marc and Tomas Persson, the primary objectives were clear; create a sail that offers light handling, a broad wind range, a balanced feel, and a more forward-driven performance.

For the larger sail sizes, maneuverability has been significantly enhanced through an increased aspect ratio. This adjustment is particularly beneficial for executing high-scoring maneuvers, such as double forwards, even with sail sizes ranging from 5.3 to 5.9 square meters. In contrast, the smaller sizes have been specifically optimized with a lower aspect ratio and an extended boom length, thereby expanding their wind range and enhancing performance in extreme high-wind conditions.

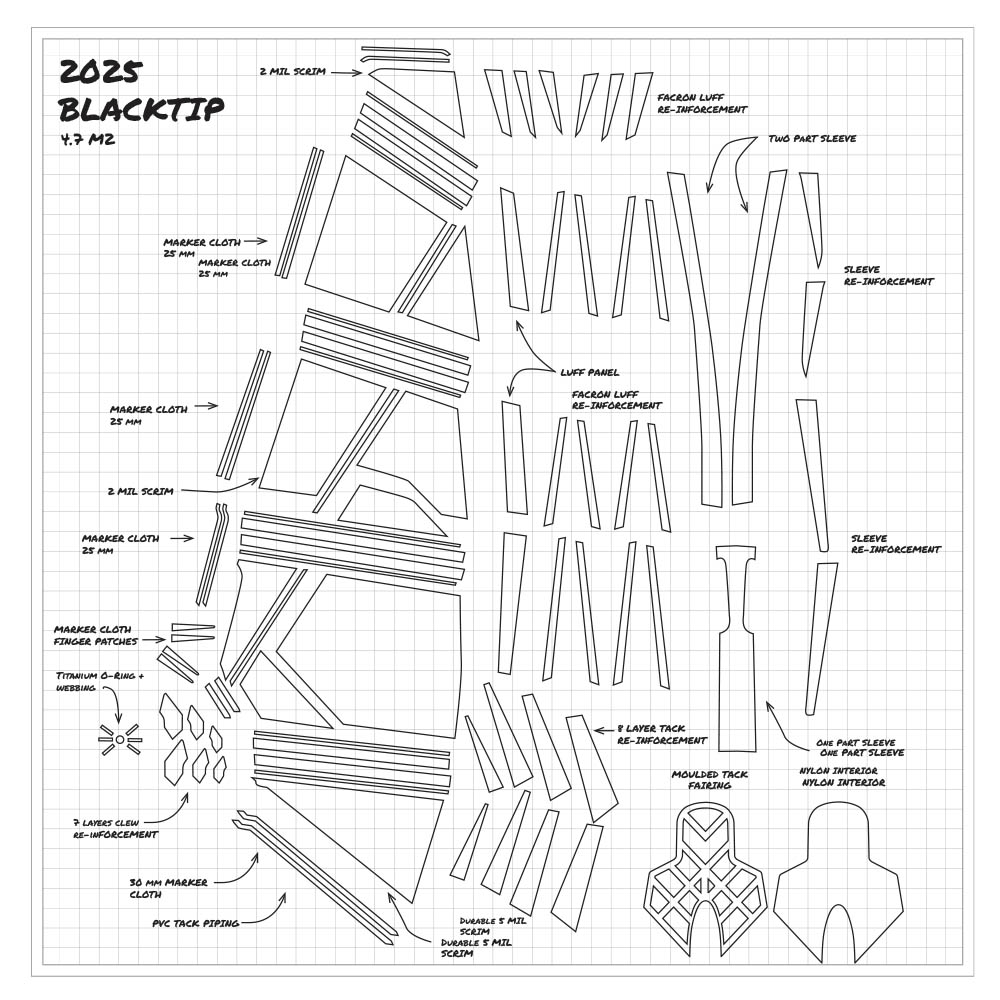

The new Blacktip incorporates a forward-focused drive, achieved by increasing the distance between the central body battens and implementing vertical shaping. This design change allows more material to fill up, creating additional drive when accelerating into powerful turns. A weight reduction of approximately6% compared to the 2024 Blacktip has been realized by refining the panel layout to minimize seams and maximizing material properties, taping, overlapping scrims, eliminating unnecessary use of marker cloth using infusion printing for graphics, and redesigning the tack fairing to further reduce weight. Ease of use has also been a critical design consideration. The luff curve has been finely adjusted so that when the sail catches a gust, it accelerates smoothly without destabilizing, to ensure optimal performance in all conditions.

Key Improvements on the 2025 BLACKTIP

// Lighter weight

// Improved forward drive

// Improved ease of use

// Increased wind range on the smaller size

// Increased maneuverability on the larger sizes

Specs

| fixed | boom | luff | mast | main window | rec mast | pro performance mast | top | battens | weight (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 3.1 | 135 | 334 | 340 | mono | SX8 RDM | SX10 RDM | adjustable | 4 | 2.54 |

| 3.4 | 142 | 343 | 340 | mono | SX8 RDM | SX10 RDM | adjustable | 4 | 2.66 |

| 3.7 | 143 | 353 | 340 | mono | SX8 RDM | SX10 RDM | adjustable | 4 | 2.78 |

| 4.0 | 147 | 364 | 340 | mono | SX8 RDM | SX10 RDM | adjustable | 4 | 2.84 |

| 4.2 | 149 | 374 | 370 | mono | SX8 RDM | SX10 RDM | fixed | 4 | 2.86 |

| 4.5 | 156 | 386 | 370 | mono | SX8 RDM | SX10 RDM | fixed | 4 | 2.95 |

| 4.7 | 159 | 394 | 370 | mono | SX8 RDM | SX10 RDM | fixed | 4 | 3.00 |

| 5.0 | 162 | 407 | 400 | mono | SX8 RDM | SX10 RDM | fixed | 4 | 3.10 |

| 5.3 | 166 | 419 | 400 | mono | SX8 RDM | SX10 RDM | fixed | 4 | 3.22 |

| 5.6 | 169 | 433 | 430 | mono | SX8 RDM | SX10 RDM | fixed | 4 | 3.32 |

| 5.9 | 178 | 447 | 430 | mono | SX8 RDM | SX10 RDM | fixed | 4 | 3.40 |

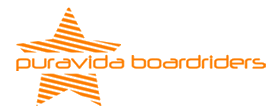

NEW! Laminate Vertical Load Line

The new laminated load line, running from the top to the tack, locks the sail profile in place even during strong gusts, enhancing stability. It also increases the material’s longevity, ensuring consistent performance. Now available in a lighter construction with the same stiffness.

NEW! Laminate Stretch Control Tendons

The Stretch Control Tendons distribute the load evenly across the sail surface, from clew to luff. They manage the twist’s breaking point, expand the wind range, and enhance the sail’s longevity. Originally a Simmer Style innovation, this feature has since been adopted by many other sail brands. Now available in a lighter construction with the same elongation properties.

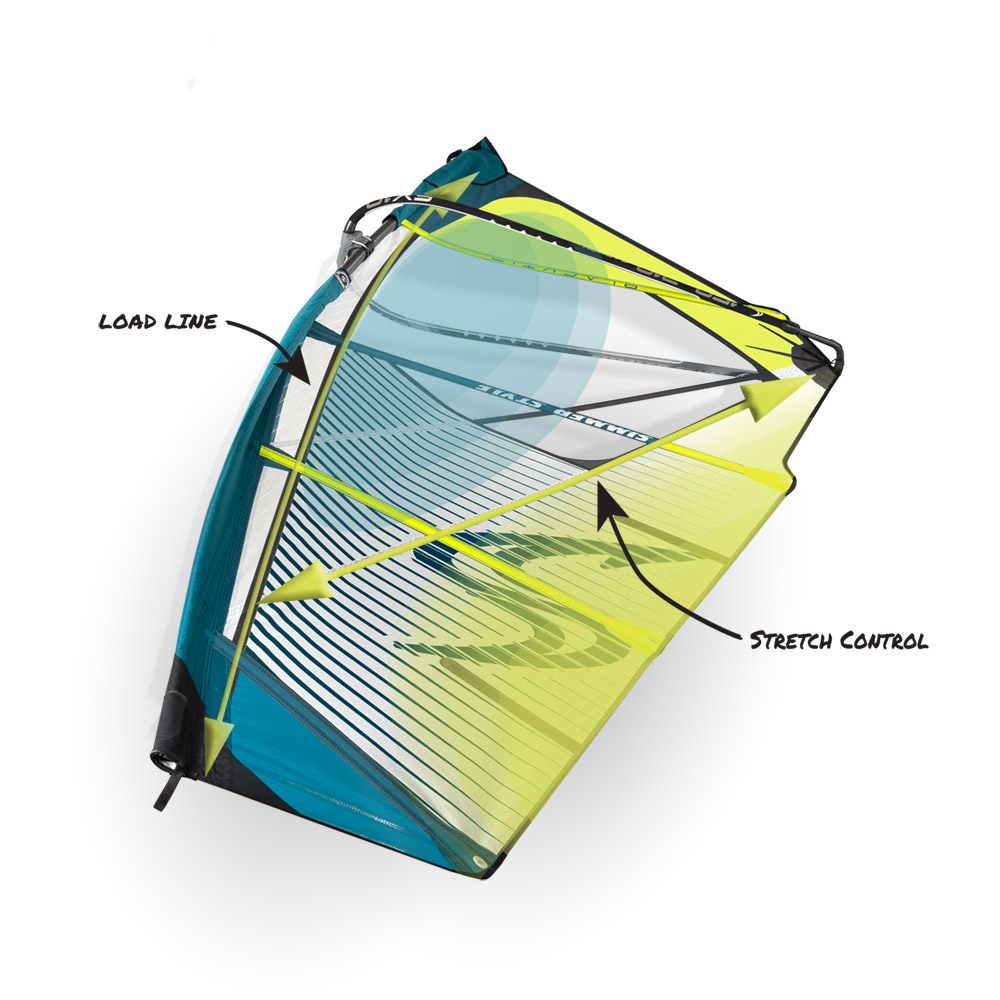

Lightweight Construction, Strength Were It’s Needed

We only use the most durable laminate scrims on the market. 100% polyester film with high stretch resilience thread reinforcement. The layers of film are bonded together with a UV resistance glue. We only use lighter scrims (less strong materials) in areas where the swing weight is reduced and where the loading is fairly low. Our focus is not to build the lightest sail weighing sail on a scale. But to build the lightest sail in terms of feeling without sacrificing durability. All our laminate scrims are made by the leading manufacturer, Dimension Polyant in the USA.

Custom tapered CGF battens

Each batten in the Blacktip features a customized CNC-machined taper and material layup, carefully engineered to maintain the sail draft in the exact position required for ideal performance. Our battens are built with over 50 layers of fiberglass and carbon, laminated under extreme pressure to achieve the maximum strength-to-weight ratio.

Durability Redefined: Layered Clew for Extreme Load Performance

The clew of a sail is a high-stress area, which is why all Simmer Style sails feature seven layers of reinforcement, along with an additional six overlapping layers from the finger tendons. These finger tendons distribute the load over a larger surface area of the sailcloth, enhancing durability and providing more direct handling. On our wave sails, we also use a stainless steel O-ring secured with six layers of durable nylon webbing. This is what defines Simmer quality.

NEW! Infusion Printing

Infusion printing embeds graphics directly into the scrims fibers, ensuring durability without adding weight. This technique preserves the sail’s flexibility and strength, allowing it to handle harsh conditions like UV exposure and saltwater while maintaining the high-performance standards Simmer is known for.

Superior Built Quality

A Blacktip is assembled from over 200 different parts. All the sail panels are cut using a CNC laser with an 0.2 mm accurate precision. This ensures that every sail coming out from the factory has the exact design according to our specifications. We know this because of all the hours spent on the factory floor and then testing our products in the world’s toughest test lab.

| Sail Size | 3.1, 3.4, 3.7, 4.0, 4.2, 4.5, 4.7, 5.0, 5.3, 5.6, 5.9 |

|---|---|

| Colour | Deep Red/Blue, White/Bold Yellow |

Related products

Simmer Style

WINDSURF

Foil Packages

Simmer 2024

WINDSURF ACCESSORIES

Simmer 2024

WINDSURF

WINDSURF

WINDSURF SAILS

WINDSURF

WINDSURF

WINDSURF SAILS