North Wave Clear Sail

£919.00 – £1,169.00

North Wave Clear Sail

With North Sails’ new Wave sail windsurfing has changed in ways you couldn’t have imagined. For the better. This featherweight sail wants to be thrown around. Low swing weight gives you maximum precision while doing so, allowing you to surf as hard as you are willing to push it. No stitching, no seams. All moulded into one piece out of exclusive Dyneema Aramid Fibers, giving you a super strong sail that will be in your quiver for many years to come. This sail is designed for the most radical of wave sailors in the most radical of conditions, charging down the line with a very active sailing style. The waves are its home. Truly a wave sail unlike any other sail out there today. Revolutionary technology for windsurfing, brought to you exclusively by North Sails. Go Beyond.

Features

- 3Di Molded Technology

- Integrated Material Reinforcements

- Integrated Batten Pockets

- Rock-it Batten Tensioner

- EZ Clew

- EZ Downhaul Wave

Materials

- 3Di Dyneema Aramid Tape Material

- Clear monofilm window

- 3Di Composite Luff Sleeve

Design Profile

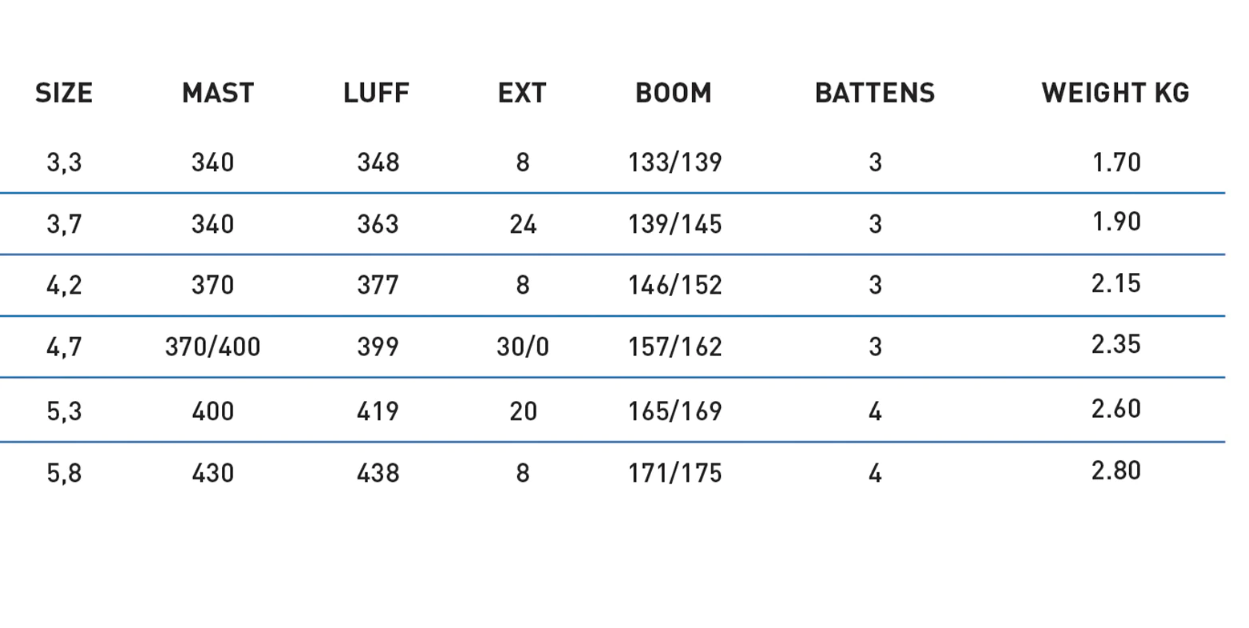

A relatively compact outline, with a slightly reduced luff length, for low swing weight in maneuvers. The profile of the wave is slightly forward-oriented, subtle enough for the sail to power up easily, but remains active, agile, and playful. 3 battens in 4.7 and smaller, 4 battens in 5.3 to 5.8, for a super smooth and lightning-quick transition between power-on and power-off. Maximum wind range, stability, and responsiveness with fewer battens, and lighter weight, thanks to the 3Di Molded Construction.

3Di Molded Technology

Molding the sails in 3D determines the shape. This means we can add unlimited shaping or twist in the sails without being limited to batten position. 3Di skins can transition seamlessly from thicker parts, to hold tension and resist impact, to other areas in the sails which are thinner, lighter and softer. 3Di Molding provides unlimited precision in sail making, unmatched in the world of windsurfing.

Dyneema Aramid

The best sails are made with a carefully engineered blend of the best performing materials. That’s why 3Di sails are composed out of Dyneema Aramid. Dyneema is up to 15 times more resistant than steel. It has very high energy absorption and very low stretch. It is extremely resistant to abrasion, humidity and UV. Aramid is what holds all the Dyneema fibers together. The end result is a composite sail that can be 3D precision molded from 1 piece without a monofilm*. It’s very strong and has a very direct feel. It translates the wind instantly into forward drive at the flick of your wrist. (*except the window).

Integrated Material Reinforcements

3Di’s composite Dyneema Aramid is layered onto the sail in tapes that are crosslinked and thermoformed together into a 1 piece composite sail. These tapes are both positioned in any orientation that you need it and layered into reinforced loads where required. This is done with no panels and no stitching. At the end of the day, the sail transitions seamlessly at microscopic levels. From a strong sail in the high wear lower foot and clew areas, to a light upper sail where the sail needs to breathe and twist. Precision use of the right quantity of materials in the right orientation results in a sail that is both 30% lighter and 3 times stronger than any other windsurf sail. Light, yet super strong.

Integrated Batten Pockets

In between the sail’s layers we use a special material, machine laid, to create the batten pocket. No seams, no panels to join, no stitching. The material bonds to the Dyneema Aramid fibers but doesn’t bond to itself. This leaves the sail with a 100% seamless and continuous fiber layout, fully integrated tunnel with space for the battens. Complex material technology with a smart result.

| Sail Size | 3.3, 3.7, 4.2, 4.7, 5.2, 5.3, 5.6, 5.8 |

|---|---|

| Colour | White |

Related products

WINDSURF

WINDSURF

WINDSURF

WINDSURF

WINDSURF

WINDSURF

WINDSURF

WINDSURF

WINDSURF